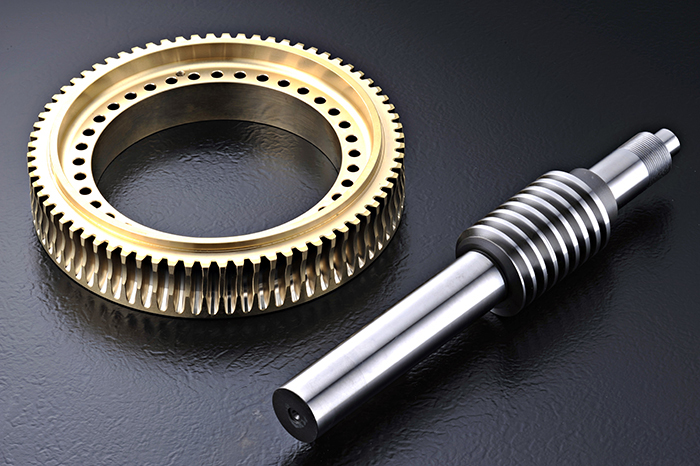

Japan-Made worm and gear

- SELLING POINT

- ABRASION TEST

- TENSILE TEST

SELLING POINT

The unique selling point of TJR worm gear

|

Others | |

|---|---|---|

| The worm gear material | Made in Japan, High tensile brass with Japanese unique formula. Its strength is better than others. |

Aluminum Bronze (ALBC3/ALBC1) or Phosphor Bronze (PBC2/PBC3) |

| Abrasion resistance | The abrasion resistance of High tensile brass: 25.1 mg/cm2 per 10,000m Its estimated wear life is 2.6 times longer than that of Aluminum Bronze |

The abrasion resistance of Aluminum Bronze: 65.7mg/cm2 per 10,000m |

| Wear Life | Normally 10 years of longer | At most 4 years |

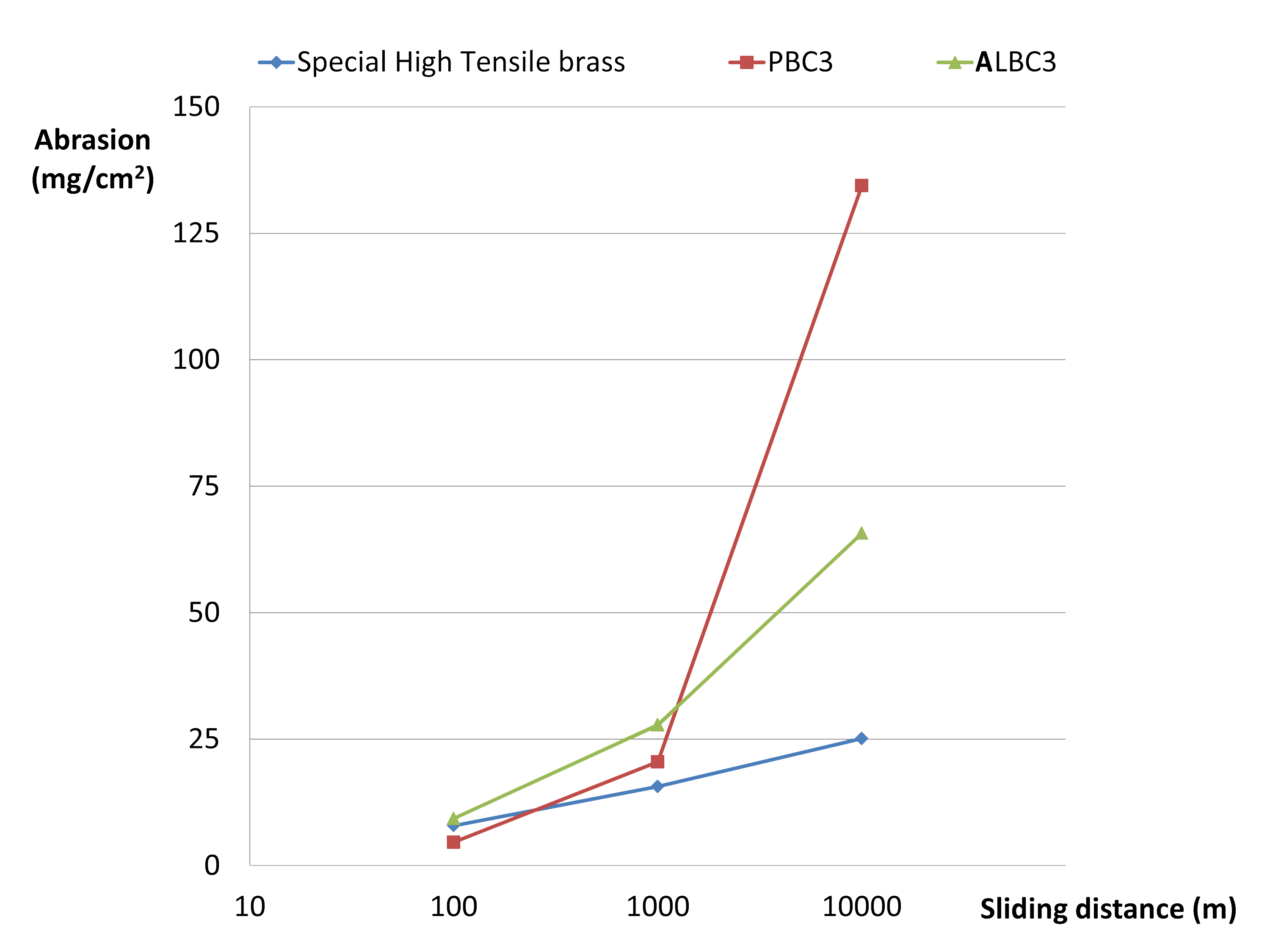

ABRASION TEST

Abrasion test for the special high tensile brass (copper compound metal)

Testing method

Under predefined conditions sliding/ abrasion test was conducted by placing the disc in the given hydraulic oil, then make the sliding surface touch three partner material pins. The ware volume per unit area was calculated based on the weight change of the disc after the test.

| Sliding Distance (m) | Abrasion (mg/cm2) | ||

|---|---|---|---|

| ALBC3 | PBC3 | Special High Tensile Brass | |

| 100 | 9.3 | 4.6 | 7.9 |

| 1000 | 27.8 | 20.5 | 15.6 |

| 10000 | 65.7 | 134.4 | 25.1 |

Abrasion resistance has increased comparing to ALBC3 and PBC3. It lengthens the machine life and improves the precision and operation rate as well.

TENSILE TEST

The special high tensile brass (copper compund metal) tensile test

| No. | Sample | Tension Testing | Sign | |||

|---|---|---|---|---|---|---|

| measurement(mm) | JIS(No) | Tensile load(kN) | Tensile strength(N/mm2) | elongation(%) | ||

| 1 | Ø14.0 | 4 | 49.4 | 321 | 6 | PBC3(1) |

| 2 | Ø14.0 | 4 | 48.3 | 314 | 6 | PBC3(2) |

| 3 | Ø14.0 | 4 | 72.2 | 474 | 8 | SpecialHigh-tensile brass |

| 4 | Ø14.0 | 4 | 75.5 | 490 | 8 | Special High-tensile brass |

| 5 | Ø14.0 | 4 | 106 | 689 | 26 | ALBC3(1) |

| 6 | Ø14.0 | 4 | 105 | 682 | 22 | ALBC3(2) |

Stronger than PBC3, and shown the strength close to that of ALBC3