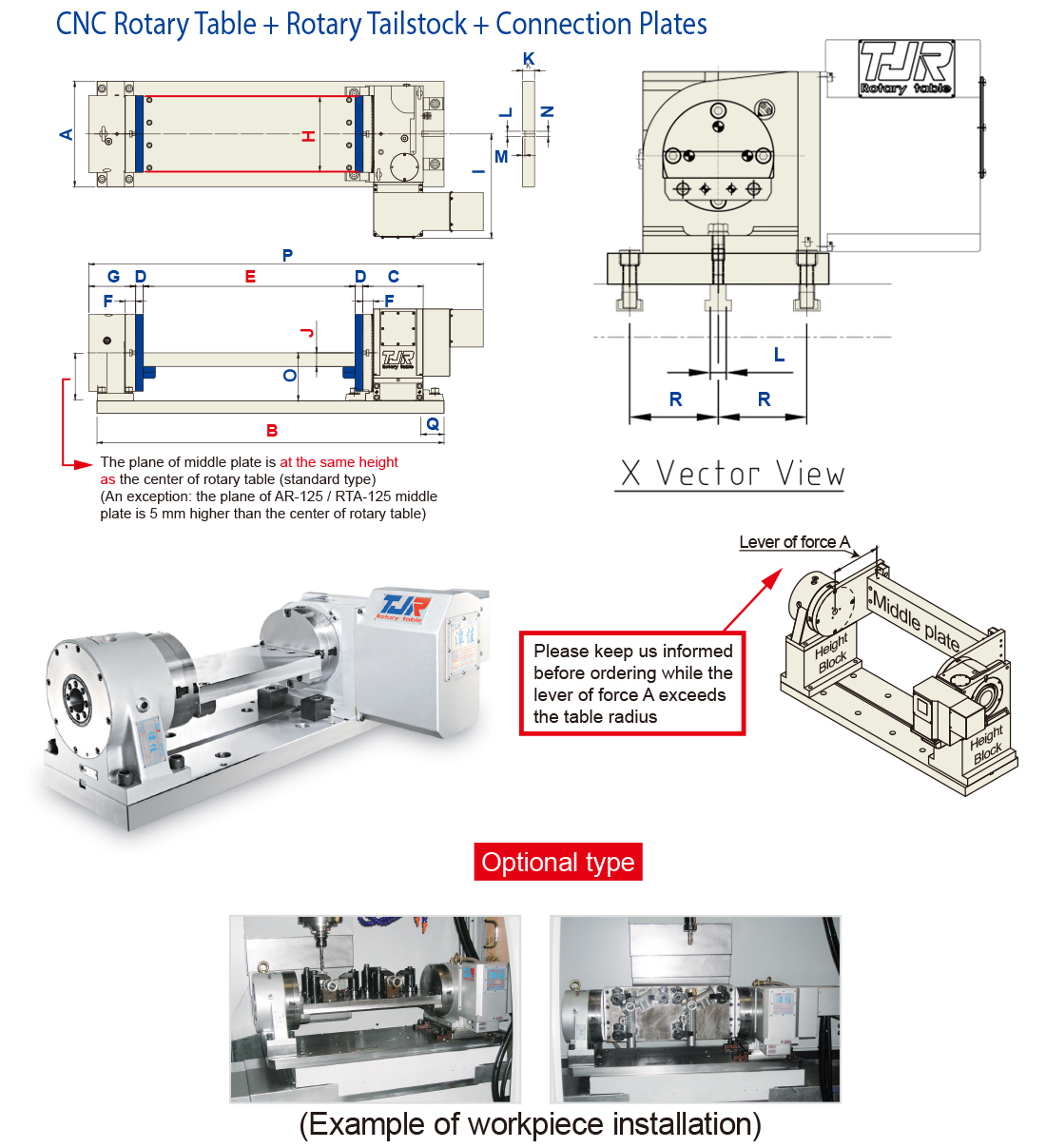

Fixture and base plates

Trunnion application can machine 3 or all the 4 sides of the component in a single setup. Thus, it gives better productivity.

Trunnion application acts like an integrated system with a support table, base plate, fixture mounting brackets, and fixture plate. Further, it gives advantages such as quick-change set-up, flexibility, and higher clamping torque due to breaks on both the rotary table and support table sides. Horizontal machine center jobs can be done on vertical machine center at a competitive machine hour rate. In fact, the trunnion application has gotten modular concept design and a drop-in rotary joint for the power clamp.

Features

1. Modular Concept Design

2. Drop-in Rotary Joint for power clamp

3. Clamps can be without plumbing

- FEATURE

FEATURE

|

| Specification |

|---|

| Model/Dimension |

| AR-125 / RTA-125 |

| AR-170(H) / RTA-170(H) |

| AR-210(H) / RTA-210(H) |

| AR-250(H) / RTA-250(H) |

| HR-255N / RTH-255 |

| HR-320N / RTH-320 |

| HR-400N / RTH-400A |

| ※ | ※ | ※ | ※ | |||||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 250 | 725 | 152 | 20 | 400 | 30 | 130 | 125 | 302 | 30 | 35 | 14 | 8 | 14 | 115 | 828 | 0 |

| 300 | 911 | 152 | 25 | 500 | 30 | 140 | 170 | 336 | 35 | 40 | 18 | 8 | 18 | 135 | 947 | 69 |

| 300 | 1011 | 152 | 25 | 600 | 30 | 140 | 200 | 336 | 40 | 40 | 18 | 8 | 18 | 160 | 1047 | 69 |

| 300 | 1020 | 160 | 25 | 600 | 38 | 140 | 250 | 336 | 40 | 40 | 18 | 8 | 18 | 160 | 1055 | 69 |

| 350 | 1148 | 200 | 25 | 700 | 35 | 155 | 250 | 346 | 45 | 40 | 18 | 8 | 18 | 160 | 1305 | 69 |

| 400 | 1297 | 235 | 30 | 800 | 40 | 160 | 300 | 416 | 45 | 40 | 18 | 8 | 18 | 210 | 1460 | 69 |

| 450 | 1455 | 250 | 30 | 900 | 45 | 175 | 400 | 457 | 45 | 40 | 18 | 8 | 18 | 255 | 1572 | 69 |

Remarks:

- ※J is the thickness of the middle plate, recommended for manufacturing. If the thickness is not enough, the middle plate will be easy to deform when twisted.