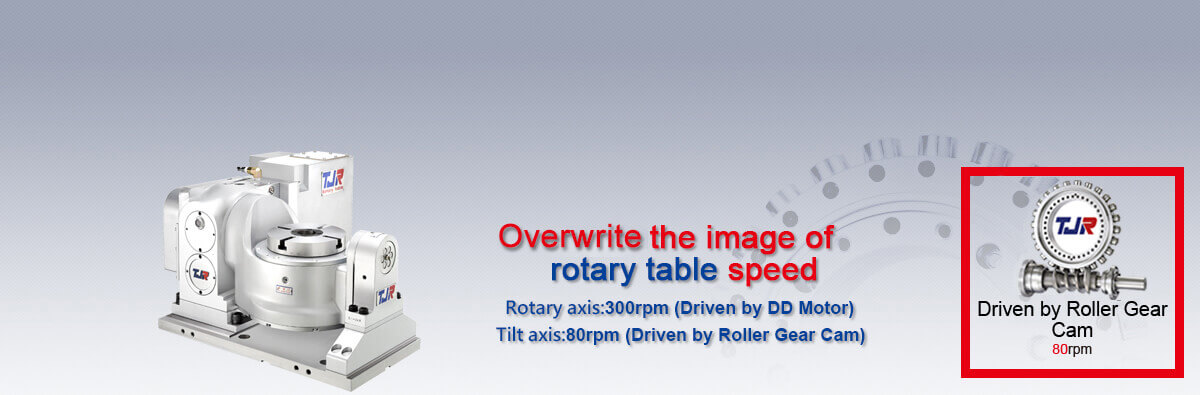

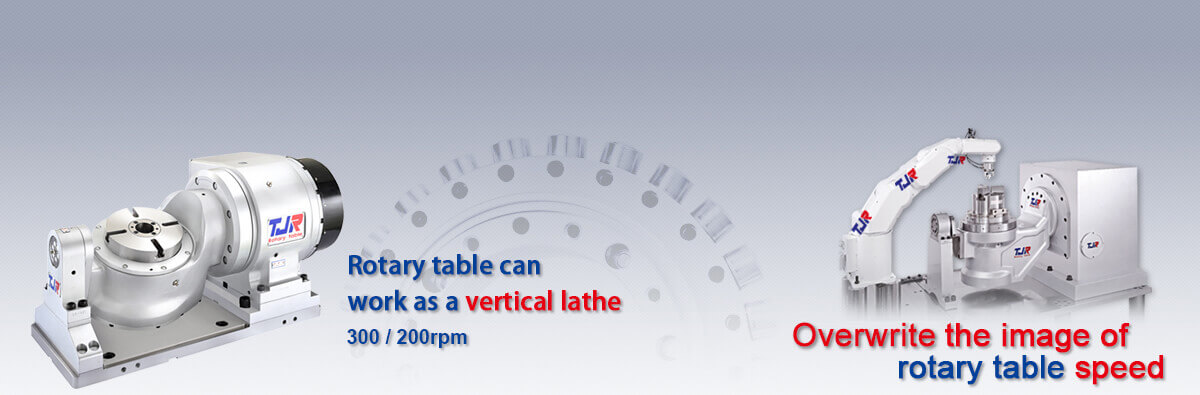

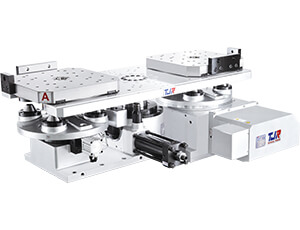

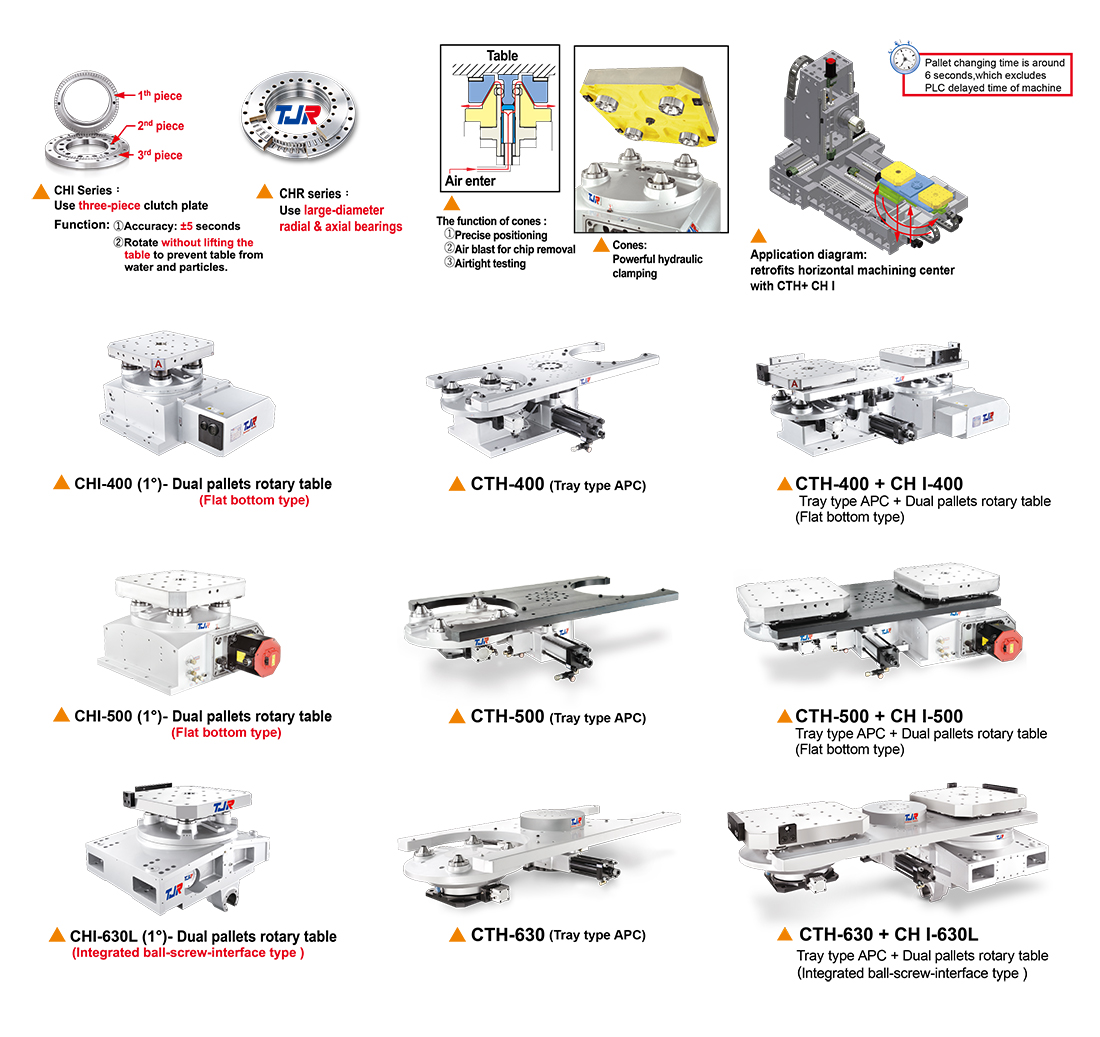

CHI/CHR Series(Dual pallets rotary table)

For horizontal machining center

CHI-400+CTH-400 / CHR-400+CTH-400

CHI-500+CTH-500 / CHR-500+CTH-500

CHI-630L+CTH-630 / CHR-630L+CTH-630

CHI/CHR Series(Dual pallets rotary table)

For horizontal machining center

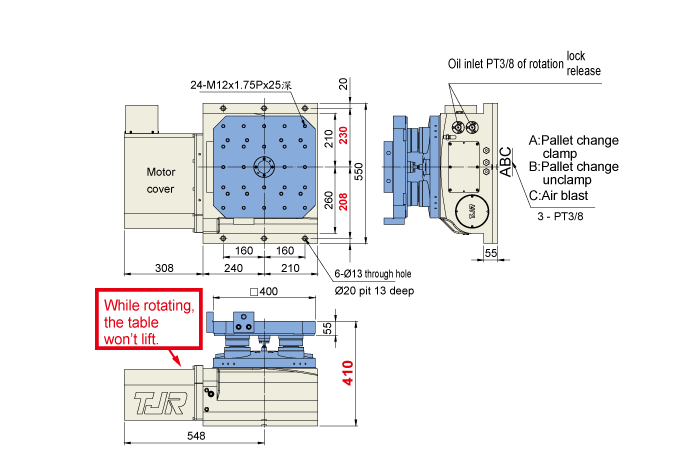

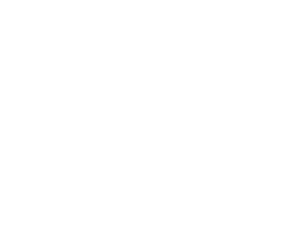

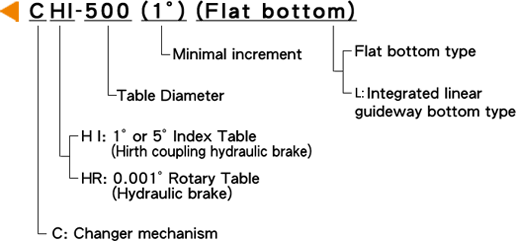

CHI-400 ( 1°or 5°)-Hirth coupling hydraulic brake / CHR-400(0.001°)-Hydraulic Brake

CHI-500 ( 1°or 5°)-Hirth coupling hydraulic brake / CHR-500(0.001°)-Hydraulic Brake

CHI-630L ( 1°or 5°)-Hirth coupling hydraulic brake / CHR-630L(0.001°)-Hydraulic Brake

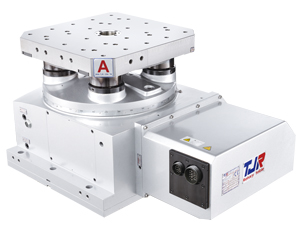

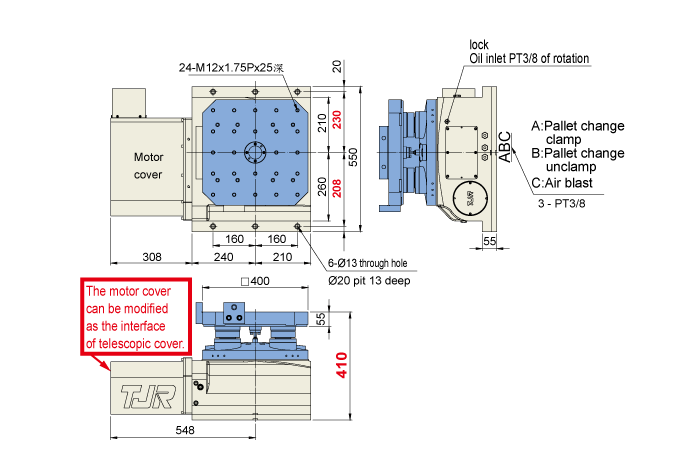

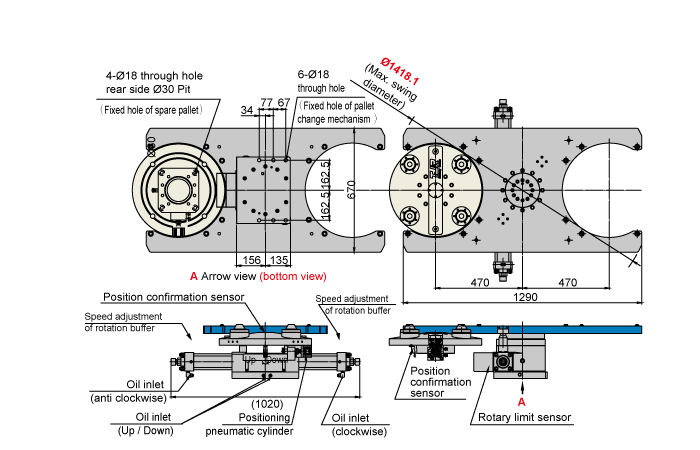

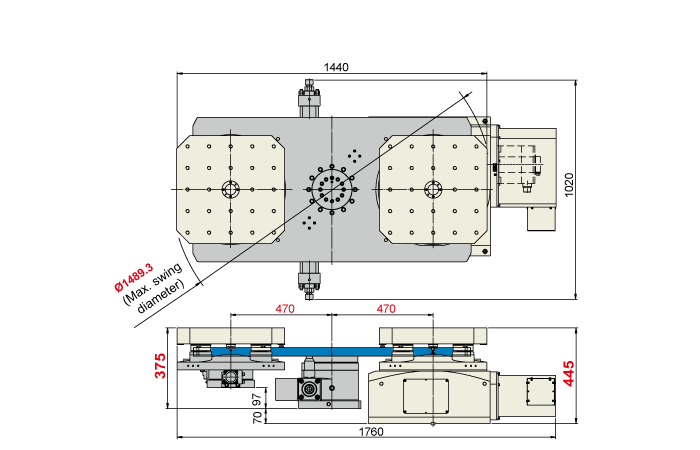

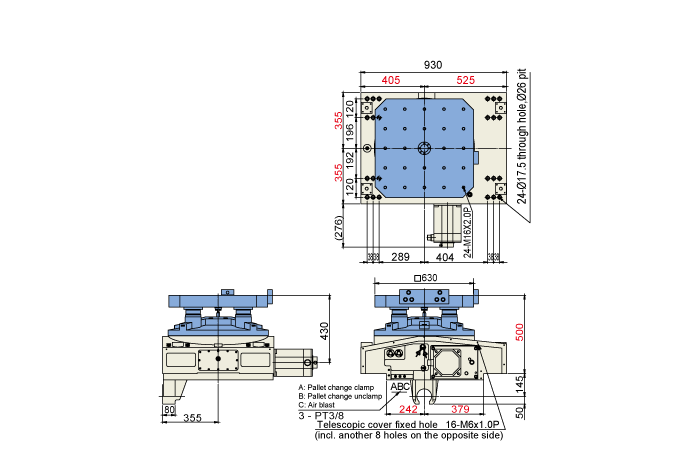

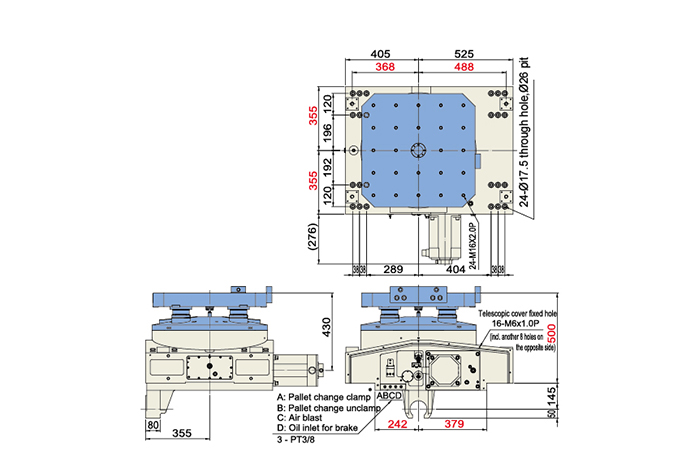

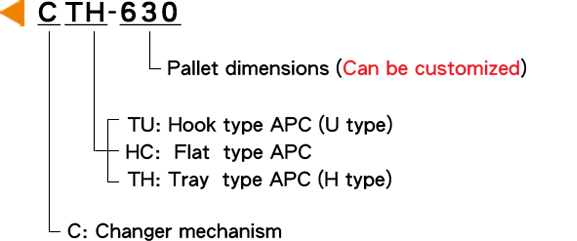

CTH Series(tray type auto pallet changer)

(180° to and fro)

Can go with CHI/CHR series

CTH-400 CTH-500 CTH-630

- SPECIFICATION

- DIMENSION

- FEATURE

SPECIFICATION

| Item/Model | Unit | |

|---|---|---|

| Table size | mm | |

| Diameter of Table Central Hole | mm | |

| Table height | mm | |

| Table T-slot Width | mm | |

| Guide Block Width | mm | |

| Min. Increment | deg. | |

| Indexing Precision | sec. | |

| Repeatability | sec. | |

| Clamping force of positioning cones(35kg/cm2) | kgf | |

| Clamping System | kg/cm2 | |

| Clamping Torque | kg-m | |

| Servo Motor Model | FANUC | Straight shaft |

| MITSUBISHI | without key | |

| Speed Reduction Ratio | - | |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) | r.p.m | |

| Allowable Workpiece Load | Horizontal |

kgf |

| Strength of worm gears | kgf | |

| Net Weight (servo motor excluded) | kg | |

| CHI-400 | CHR-400 | CHI-500 | CHR-500 | CHI-630L | CHR-630L |

|---|---|---|---|---|---|

| □400x400 | □400x400 | □500x500 | □500x500 | □630x630 | □630x630 |

| Ø50x27 deep | Ø50x27 deep | Ø50x27 deep | Ø50x27 deep | Ø50x27 deep | Ø50x27 deep |

| 410 | 410 | 445 | 445 | 500 | 500 |

| 14H7 | 14H7 | 18H7 | 18H7 | - | - |

| 18h7 | 18h7 | 18h7 | 18h7 | - | - |

| 1 or 5 | 0.001 | 1 or 5 | 0.001 | 1 or 5 | 0.001 |

| ±5 | 15 | ±5 | 15 | ±5 | 15 |

| ±1 | 6 | ±1 | 6 | ±1 | 6 |

| 960x4=3840 | 960x4=3840 | 960x4=3840 | 960x4=3840 | 960x4=3840 | 960x4=3840 |

| 35 | 35 | Hydraulic 35 | Hydraulic 35 | Hydraulic 35 | Hydraulic 35 |

| 500 | 200 | 1000 | 370 | 5000 | 800 |

| αiF12 / ßiS22 | αiF12 / ßiS22 | ßiS22 | αiF12 / ßiS22 | ßiS22 | αiF22 / ßiS22 |

| HG / HF-204S | HG / HF-204S | HG / HF-204 | HG / HF-204 | HG / HF-204 | HG / HF-204 |

| 1:120 | 1:120 | 1:180 | 1:180 | 1:180 | 1:180 |

| 25 | 25 | 16.6 | 16.6 | 16.6 | 16.6 |

| 400 | 400 | 600 | 600 | 1200 | 1200 |

| - | 170 | - | 250 | - | 420 |

| 410 | - | 716(including 2 pallets) | - | 1135 | - |

| Item/Model | Unit | |

|---|---|---|

| Lift-up mechanism | - | |

| Table size | mm | |

| Rotation method | - | |

| Rotation angle | - | |

| Clamping System | kg/cm2 | |

| Positioning method | - | |

| Clamping force (35kg/cm2) | kgf | |

| Operating System(Up & Down & Rotate) | kg/cm2 | |

| Lifting thrust force | kg | |

| Up and down travel of the pallet | mm | |

| Allowable Workpiece Load | Horizontal |

kgf |

| Inspection accuracy | ||

| Repeatability accuracy on positioning of the same pallet | mm | |

| Max. positioning tolerance for 2 pallets | mm | |

| Parallelism of pallet top and base bottom | mm | |

| CTH-400 | CTH-500 | CTH-630 |

|---|---|---|

| Tray type ( H type ) | Tray type ( H type ) | Tray type ( H type ) |

| 520 x 1140 | 670 x 1290 | 834 x 1700 |

| Hydraulic hirth coupling | Hydraulic hirth coupling | Hydraulic hirth coupling |

| 180º to and fro | 180º to and fro | 180º to and fro |

| Hydraulic 35 | Hydraulic 35 | Hydraulic 35 |

| Cone positioning | Cone positioning | Cone positioning |

| 960x4=3840 | 960x4=3840 | 960x4=3840 |

| Hydraulic 35 | Hydraulic 45 | Hydraulic 45 |

| 2200 | 2860 | 3780 |

| 60 | 60 | 60 |

| 400x2=800 | 500x2=1000 | 1000x2=2000 |

| 0.01 | 0.01 | 0.01 |

| 0.02 | 0.02 | 0.02 |

| 0.02 | 0.02 | 0.02 |

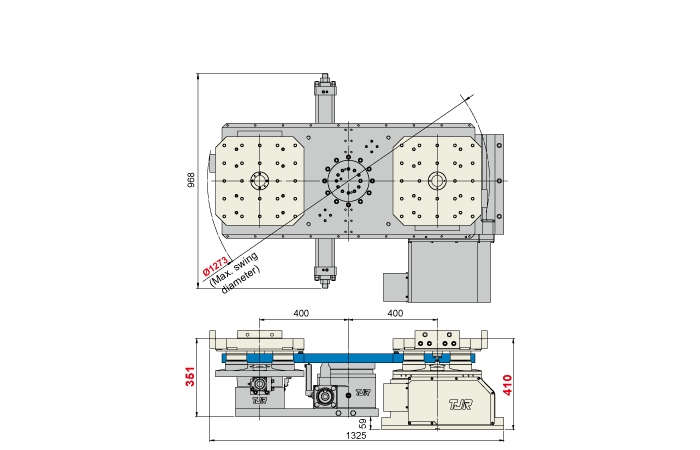

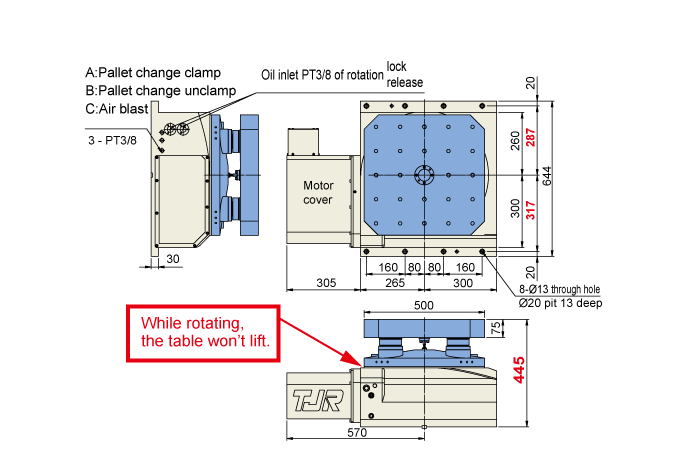

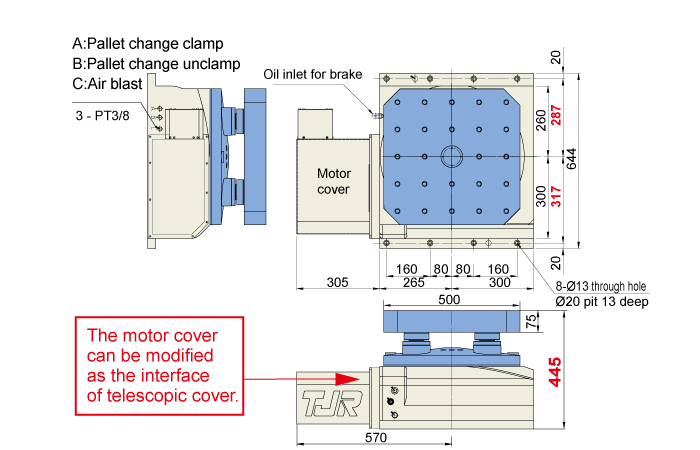

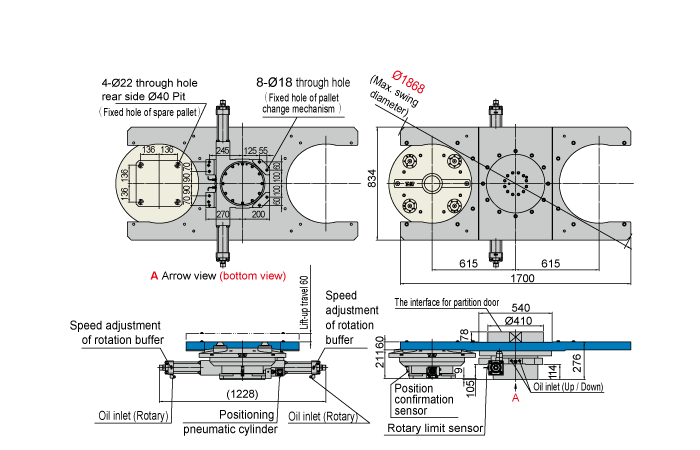

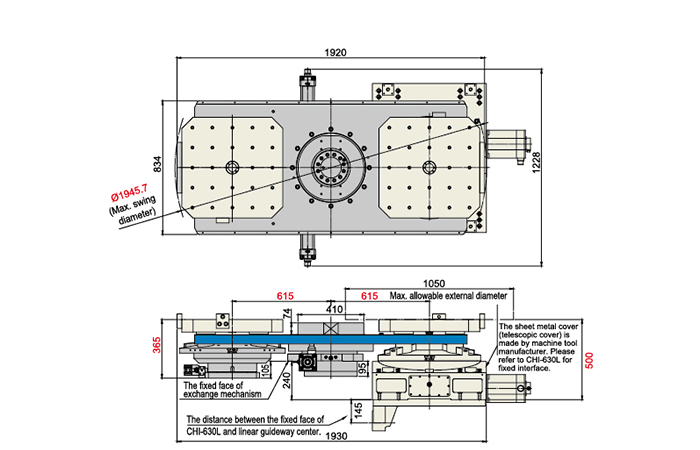

DIMENSION

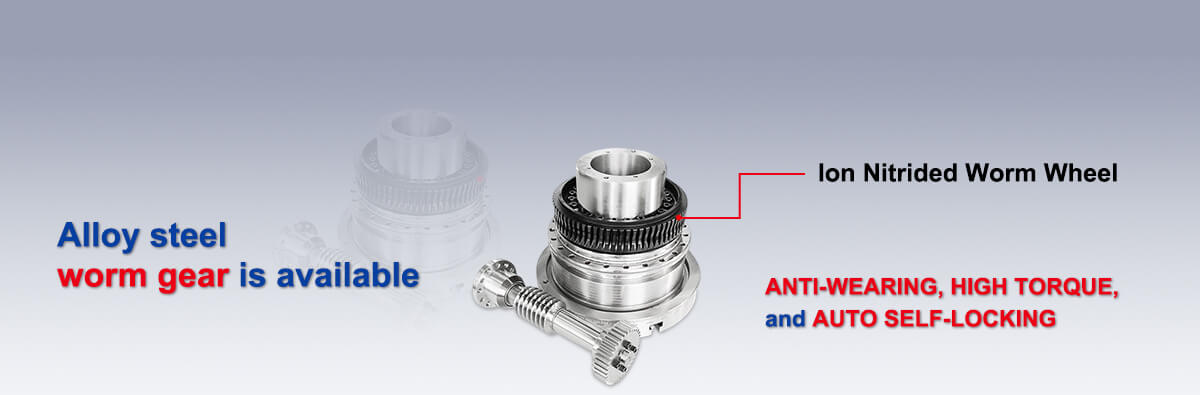

FEATURE

|