| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Pneumatic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

| FHR(s)-255C / 255CL |

| Ø 255 |

| Ø 110 |

| Ø 80H7 |

| Ø 80 |

| 290 |

| 12H7 |

| 18h7 |

| Rotation |

Tilt ±110º |

| 0.001 |

0.001 |

| 15 |

60 *¹ |

| 6 |

8 |

| 35 |

35 |

| 70 |

140 |

| αiF4 / αiF8 / αiS12 / ßiS8(Taper) |

αiF8 / αiS12 / ßiS12(Taper) |

| HG/HF-104 |

HG/HF-154 |

| 1:120 |

1:120 |

| 33.3 * (25) |

16.6 * (11.1) |

| 8.13 |

| 100 |

| 75 |

| 1500 |

| 140 |

| 70 |

| 55 *(31) |

| 296(Ø255C) / 312(Ø255CL) |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

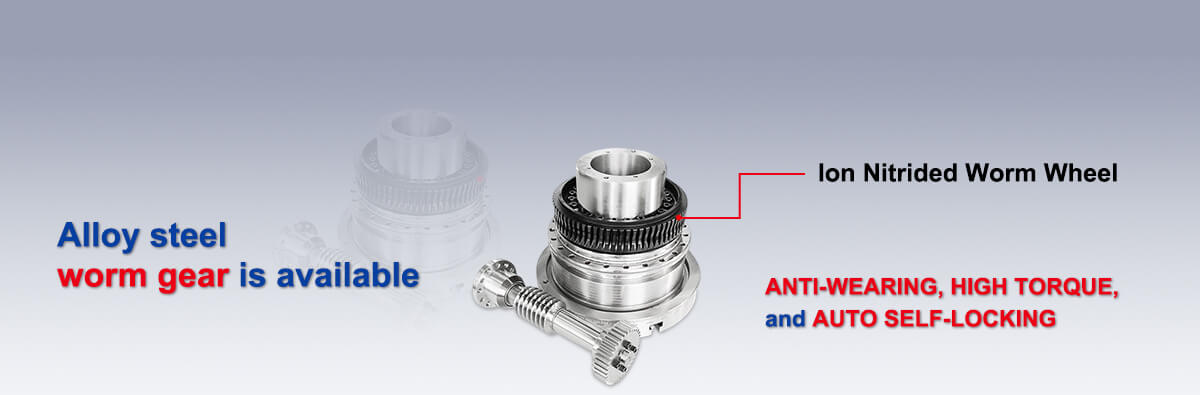

- ★*()Alloy Steel worm & gear series.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Pneumatic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

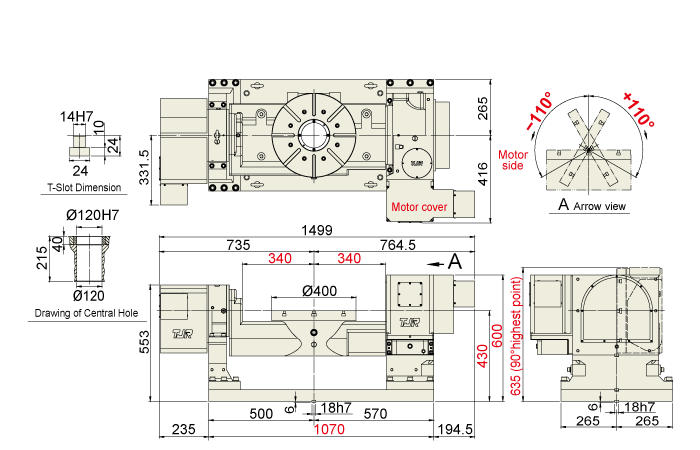

| FHR-320 (Standard type) |

FHR-320C (Cradle type) |

| Ø 320 |

Ø 320 |

| Ø 150 |

Ø 150 |

| Ø 120H7 |

Ø 120H7x30 deep |

| Ø 120 |

Ø 80 |

| 355 |

310 |

| 14H7 |

14H7 |

| 18h7 |

18h7 |

| Rotation |

Tilt ±100º |

Rotation |

Tilt ±100º |

| 0.001 |

0.001 |

0.001 |

0.001 |

| 15 |

50 *¹ |

15 |

60 *¹ |

| 6 |

8 |

6 |

8 |

| 35 |

35 |

35 |

35 |

| 115 |

175 |

70 |

175 |

| αiF8 / αiS12 / ßiS12(Taper) |

αiF12 / ßiS22(Straight) |

αiF8 / αiS12 / ßiS12(Taper) |

αiF12 / ßiS22(Straight) |

| HG/HF-104 |

HG/HF-204 |

HG/HF-104 |

HG/HF-204 |

| 1:120 |

1:120 |

1:120 |

1:120 |

| 25 |

16.6 |

25 |

16.6 |

| 25.6 |

25.6 |

| 200 |

200 |

| 150 |

100 |

| 1800 |

1800 |

| 175 |

175 |

| 115 |

70 |

| 80 |

55 |

| 470 |

489 |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Pneumatic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

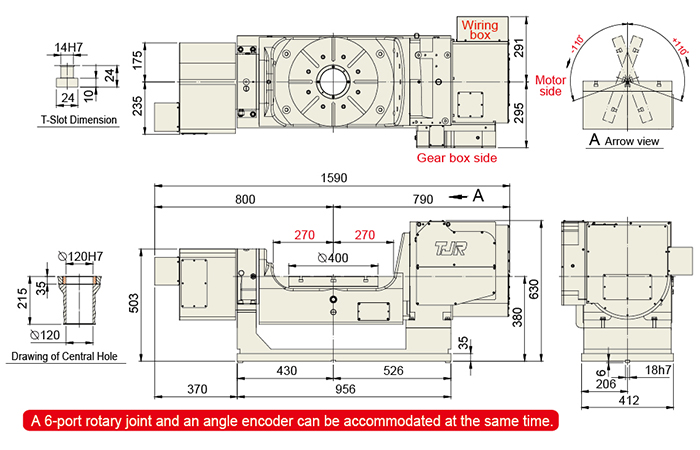

| FHR-400CF (Cradle type) |

| Ø 400 |

| Ø150H7 |

| Ø 120H7x40 deep |

| Ø 120 |

| 430 |

| 14H7 |

| 18h7 |

| Rotation |

Tilt ±100º |

| 0.001 |

0.001 |

| 15 |

60 *¹ |

| 6 |

8 |

| 35 |

35 |

| 115 |

175 |

| αiF8 / αiS12 / ßiS12 (Straight) |

αiF12 / ßiS22 (Straight) |

| HG/HF-154 |

HG/HF-354 |

| 1:120 |

1:120 |

| 25 |

16.6 |

| 40 |

| 200 |

| 100 |

| 1800 |

| 175 |

| 115 |

| 80 |

| 818 |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Pneumatic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

| FHR-400C-540-HR400B (Cradle type) |

| Ø 400 |

| Ø150H7 |

| Ø 120H7x35 deep |

| Ø 120 |

| 380 |

| 14H7 |

| 18h7 |

| Rotation |

Tilt ±100º |

| 0.001 |

0.001 |

| 15 |

60 *¹ |

| 6 |

6 |

| 35 |

35 |

| 115 |

275 |

| αiS12 |

αiF22 |

| HF/HG-154 |

HF/HG-354 |

| 1:120 |

1:120 |

| 25 |

16.6 |

| 44 |

| 220 |

| 120 |

| 1800 |

| 275 |

| 115 |

| 80 |

| 702 |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Pneumatic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

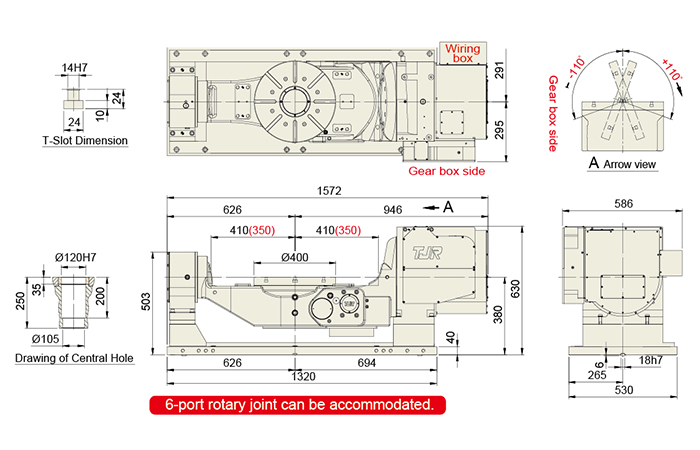

| FHR-401C-820(700)-HR400B (Cradle type) |

| Ø 400 |

| Ø150H7 |

| Ø 120H7x35 deep |

| Ø 105 |

| 410 |

| 14H7 |

| 18h7 |

| Rotation |

Tilt ±100º |

| 0.001 |

0.001 |

| 15 |

60 *¹ |

| 6 |

6 |

| 35 |

35 |

| 115 |

275 |

| αiF8/αiS12/βiS12(Taper) |

αiF22/βiS22(Straight) |

| HF/HG-154 |

HF/HG-354 |

| 1:120 |

1:120 |

| 25 |

16.6 |

| 44 |

| 220 |

| 120 |

| 1800 |

| 275 |

| 115 |

| 80 |

| 958 |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

| Item/Model |

Unit |

| Table Diameter |

mm |

| Diameter of Table Central Hole |

mm |

| Inner Diameter of Mandrel Sleeve |

mm |

| Diameter of Center Through Hole |

mm |

| Table Height (Horizontal) |

mm |

| Table T-slot Width |

mm |

| Guide Block Width |

mm |

| Axis |

|

| Min. Increment |

deg. |

| Indexing Precision |

sec. |

| Repeatability |

sec. |

Clamping System (Hydraulic)

|

kg/cm2 |

| Clamping Torque |

kg-m |

| Servo Motor Model |

FANUC |

Taper/Straight shaft |

| MITSUBISHI |

Taper shaft |

| Speed Reduction Ratio |

- |

| Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

| Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

| Allowable Workpiece Load |

0º Horizontal |

kg |

0º~90º Tilt |

kg |

| Allowable Load(with Rotary Table Clamping) |

F |

kgf |

FxL |

kgf.m |

FxL |

kgf.m |

Strength of worm gears (Rotary axis) |

kg.m |

| Net Weight (servo motor excluded) |

kg |

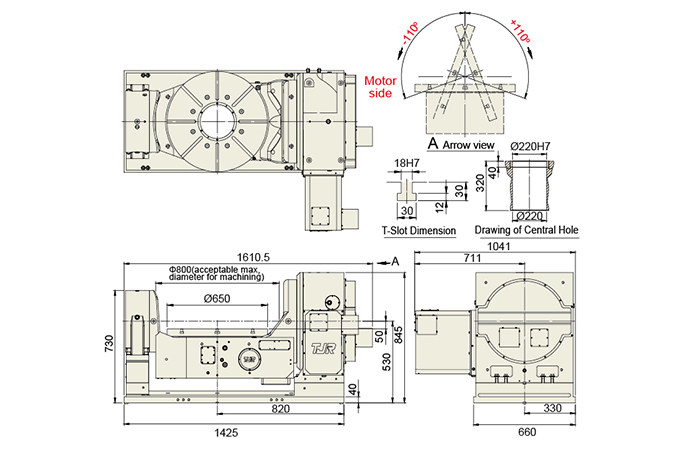

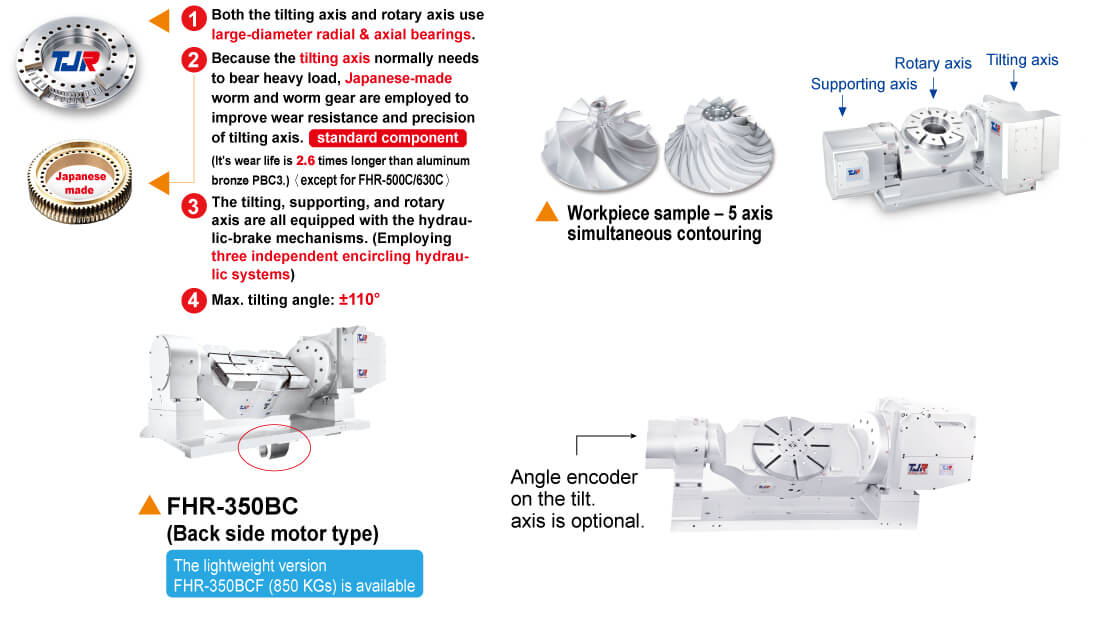

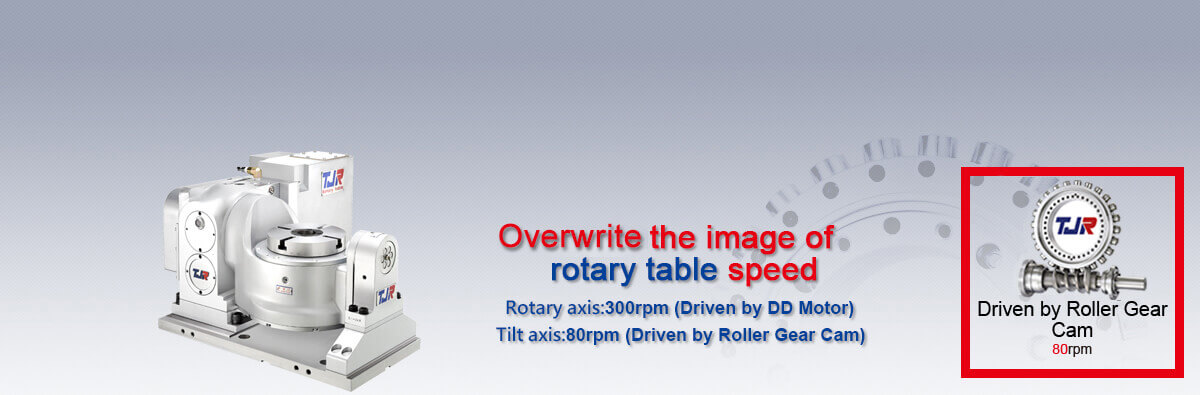

| FHR-500C(dual-arm, cradle type) |

FHR-650C(dual-arm, cradle type) |

| Ø500 |

Ø650 |

| Ø250x40 deep |

Ø250x40 deep |

| Ø 220H7 |

Ø 220H7 |

| Ø 220 |

Ø 220 |

| 440 |

480 |

| 18H7 |

18H7 |

| 18h7 |

18h7 |

| Rotation |

Tilt ±110º |

Rotation |

Tilt ±100º |

| 0.001 |

0.001 |

0.001 |

0.001 |

| 15 |

60 *¹ |

15 |

60 *¹ |

| 6 |

8 |

6 |

8 |

| 35 |

35 |

35 |

35 |

| 370 |

410 |

370 |

800 |

| αiF12/βiS22 |

αiF22/βiS30 |

αiF12 |

αiF30 |

| HG/HF-204 |

HG/HF-354 |

HG/HF-204 |

HG/HF-703 |

| 1:120 |

1:180 |

1:120 |

1:180 |

| 25 |

11.1 |

25 |

11.1 |

| 93.75 |

40 |

| 500 |

500 |

| 300 |

400 |

| 3000 |

3200 |

| 410 |

800 |

| 370 |

370 |

| 250 |

250 |

| 1091 |

1867 |

※In accordance with the foreign trade control ordinance, permission of the ministry of economy, trade and industry is required when exporting dual-axis products overseas.

- ★*¹Indexing precision can be better after installing angle encoder. Please refer to the table on page 70 for more details.

-255CL-series-model.png)

-255C-3See.jpg)

-255CL-3See.jpg)

-320-3See.jpg)

-320C-3See.jpg)