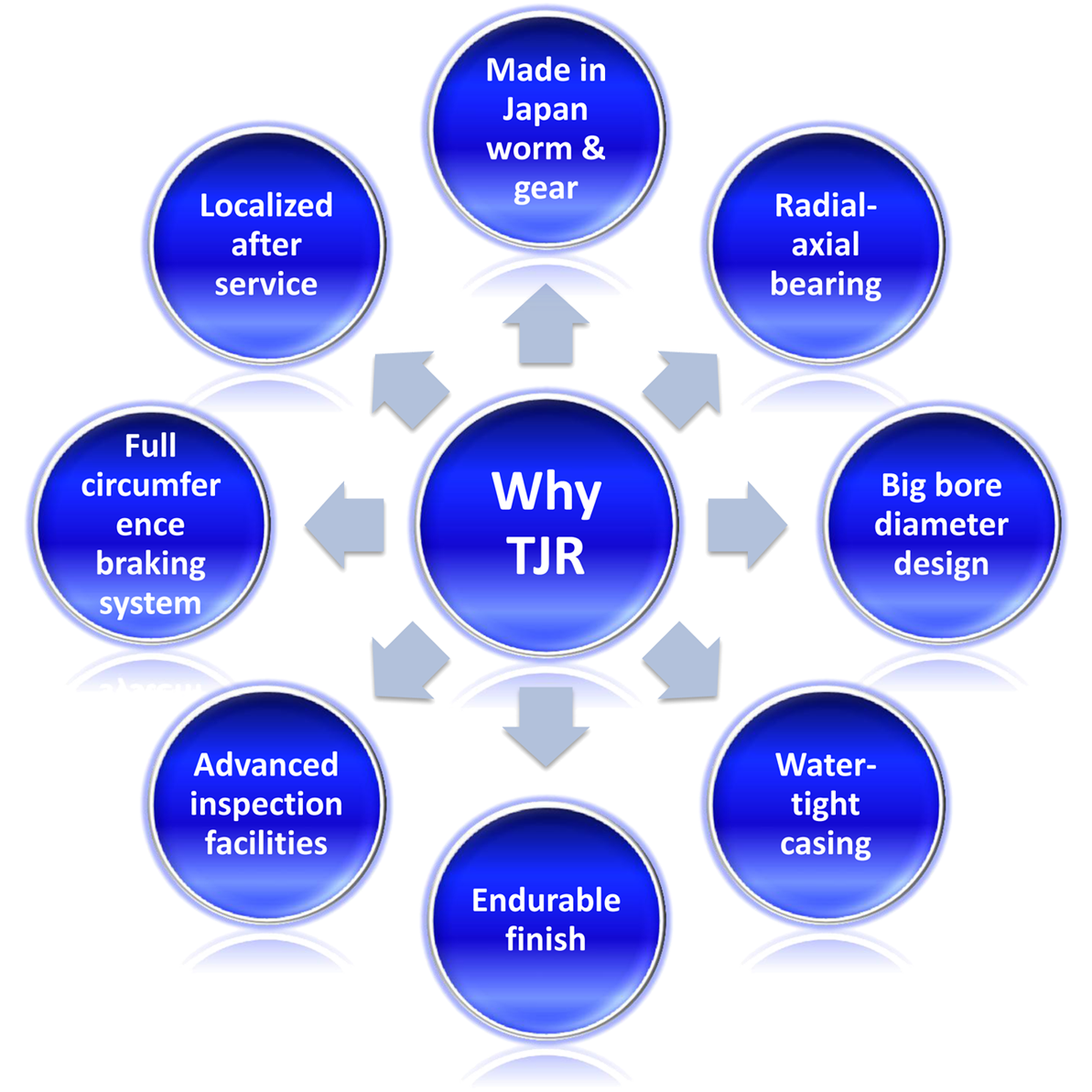

Why choose TJR

TJR Value Added Features

|

Other | |

|---|---|---|

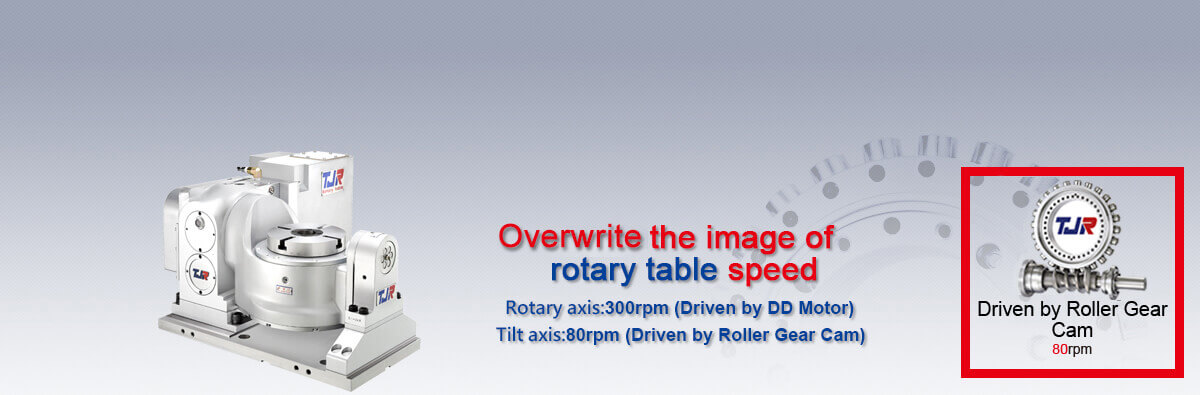

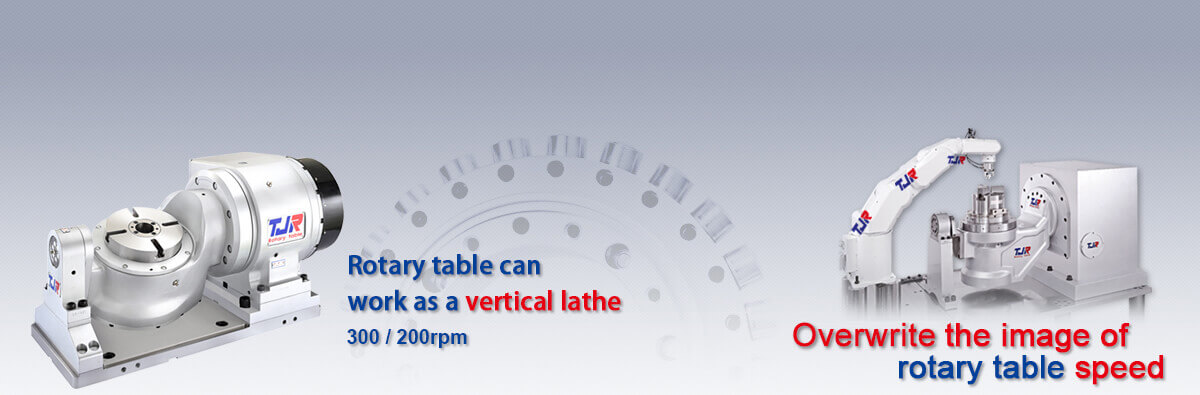

| Table rotation rate | AR-125

HR--255

High table speed, high efficiency |

The equivalent of AR-125

The equivalent of HR-255

|

| After service-support in China | Experienced after-service technicians located in China provide prompt services. | Lacking local after-service supports |

| Water Resistance | Watertight by all rims sealed with O-ring Protect class: IP65 |

Manually smear connections with waterproof glue |

| Appearance |

|

|

| Diameter of Table central hole | Large bore is the TJR standard for the entire product line | Large bore is an optional extra |

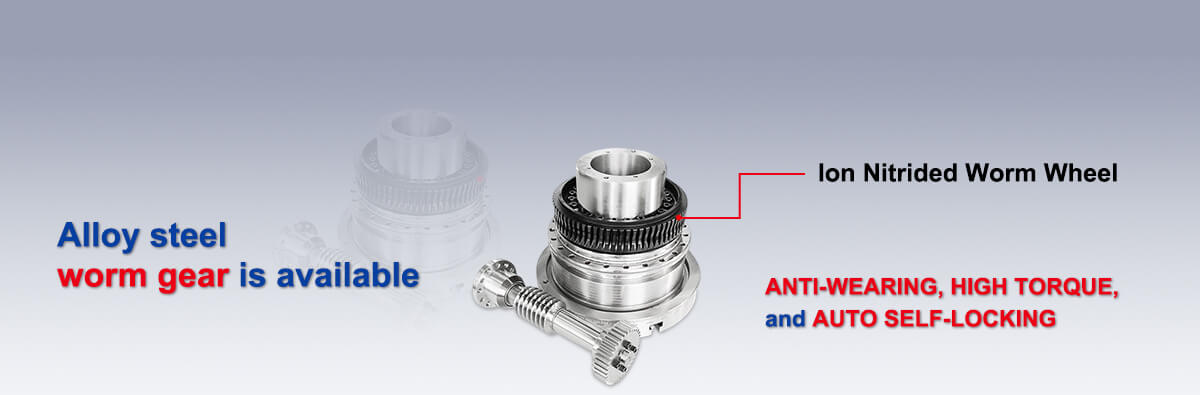

The unique selling point of TJR worm gear

|

Other | |

|---|---|---|

| The worm gear material | Made in Japan, High tensile brass with Japanese unique formula. Its strength is better than ferroalloy. |

Aluminum Bronze (ALBC3/ALBC1) or Phosphor Bronze (PBC2PBC3) |

| Abrasion resistance | The abrasion resistance of High tensile brass: 25.1 mg/cm2 per 10,000m Its estimated wear life is 2.6 times longer than that of Aluminum Bronze |

The abrasion resistance of Aluminum Bronze: 65.7mg/cm2 per 10,000m |

| Wear Life | Normally 10 years of longer | At most 4 years |

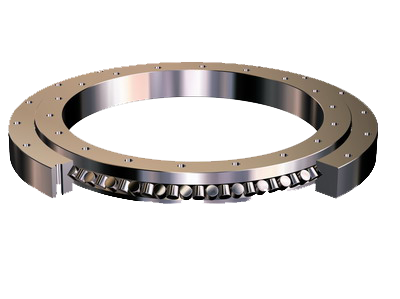

The advantage of TJR spindle bearing

|

Company A | Company B |

|---|---|---|

| Radial-axial preloading bearing | Taper roller bearing | Cross roller bearing |

|

|

|

| Can bear heavy cutting in the horizontal and verticaldirections | Can bear less heavy cutting | Can only bear light cutting |

|

|

|

|

Advanced inspection facilities

|

Others | |

|---|---|---|

| 2-Dimension coordinate measuring machine | Yes |

Yes |

| 3-Dimension coordinate measuring machine | Yes Fully utilized to test all kind of precision and runout |

None |

| Laser interferometer and rotary axis calibrator | Yes Every TJR rotary table needs to pass the test by the laser angular position measurement system before shipment |

None Some companies only use normal optical auto-collimators or height gauge collocating with fixture to test. |

High performance braking mechanism

|

Others | |

|---|---|---|

| Method | Use the full circumference braking and clamping mechanism. The braking mechanism is designed with full 360∘circumference hydraulic clamping.

|

Use the conventional disk braking systems.

|